Anti Corrosion – Anti Contamination – Self Cleaning – Anti Wetting Product Nano Technology

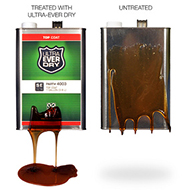

Ultra Ever Dry

Ultra-Ever Dry is a superhydrophobic (water) and oleophobic (hydrocarbons) coating that will repel most water-based and some oil-based liquids. Ultra-Ever Dry uses proprietary omniphobic technology to coat an object and create a surface chemistry and texture with patterns of geometric shapes that have “peaks” or “high points”. These high points repel water, some oils, wet concrete, and other liquids unlike any other coating.

Ultra-Ever Dry has vastly improved adhesion and abrasion resistance, compared to previous superhydrophobic technologies, allowing it to be used in applications where greater durability is required.

Anti-Wetting : The superhydrophobic coating keeps objects dry. Water and many other liquids are easily repelled.

Anti-Corrosion : Ultra-Ever Dry offers enhanced corrosion protection since the superhydrophobic coating repels water, saltwater, aqueous acids and bases.

Anti-Icing : The superhydrophobic properties of Ultra-Ever Dry keep coated materials completely dry, eliminating the formation of ice or, in the case of frost, making the removal of ice dramatically easier.

Anti-Contamination : Water and other liquids that contain bacteria or radiation never actually contact the surface of the coated material so bacteria and radiation is greatly diminished or eliminated and the surface is easy to decontaminate. Dust and dirt are easily removed with low pressure water.

Self-Cleaning : Ultra-Ever Dry repels dirty water and some oils, and remains clean and virtually bacteria-free. When dust, dirt or other molecules accumulate on a superhydrophobic coated surface, a light spray of water or a blast of air grabs the dust and removes it.Product Life-Extending – Many products fail from moisture, water, oil or simply getting too dirty for continued use. Use Ultra-Ever Dry superhydrophobic coating to extend the life of electric motors by preventing the build up of moisture on the windings, coat nuts and bolts to prevent corrosion, coat tools, equipment, and virtually any item that needs to be kept dry, corrosion free, de-iced, uncontaminated or clean. Save money, improve safety and create a cleaner work environment.

Product Life Extending : Many products fail from moisture, water, oil or simply getting too dirty for continued use. Use Ultra-Ever Dry superhydrophobic coating to extend the life of electric motors by preventing the build up of moisture on the windings, coat nuts and bolts to prevent corrosion, coat tools, equipment, and virtually any item that needs to be kept dry, corrosion free, de-iced, uncontaminated or clean. Save money, improve safety and create a cleaner work environment.

Applications : Some of the ways that Ultra-Ever Dry can be used.

- Bricks

- Industrial electronics

- Engines

- Protection from acids/bases

- Tools & equipment

- Paint equipment

- Air stripper trays

- Nuts, bolts and other hardware

- Cement trucks & pumps

- Prevent buildup

- Building supplies

- Boats & marinas

- Machinery

- Electric motors

- Paper mill wet section equipment

- Cinder blocks

- Corrosion prevention

- Fall protection

- Cooling coils

- Condensers

- HVAC

- Work vehicles

- Water proofing

| Part Number | Description | Color | Size | Average Coverage Sq Ft(sq.m) |

|---|---|---|---|---|

| 4000 | Ultra-Ever Dry, Bottom Coat* | Translucent White | 1 Quart | 62.5 (6) |

| 4001 | Ultra-Ever Dry, Top Coat* | Translucent White | 1 Quart | 62.5 (6) |

| 4002 | Ultra-Ever Dry, Bottom Coat* | Translucent White | 1 Gallon | 250 (23) |

| 4003 | Ultra-Ever Dry, Top Coat* | Translucent White | 1 Gallon | 250 (23) |

| 4004 | Ultra-Ever Dry, Bottom Coat* | Translucent White | 5 Gallon | 1250 (116) |

| 4005 | Ultra-Ever Dry, Top Coat* | Translucent White | 5 Gallon | 1250 (116) |

| 4008 | Ultra-Ever Dry, Bottom Coat* | Translucent White | 50 Gallon ** | 12500 (1150) |

| 4009 | Ultra-Ever Dry, Top Coat* | Translucent White | 50 Gallon | 12500 (1150) |

NOTE: Ultra-Ever Dry is a TWO-part system. Both the Bottom Coat and Top Coat must be applied for the product to be effective. FOR INDUSTRIAL USE ONLY.